| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : HYX

Model Number : HYX-MIM 2023-8-17

Certification : Rohs

Place of Origin : Shenzhen, China

MOQ : 5000 pcs

Price : 0.07~1.98 usd

Payment Terms : T/T, Western Union, MoneyGram

Supply Ability : 500000 pcs per month

Delivery Time : 20~30 days after pay

Packaging Details : 10000 pcs per carton box with 30cm*20cm*15cm

Material : Stainless steel

Surface finish : original

Hardness : 38~50 HRC

Tolerance : ISO 2768-m

Weight : 3 gram

Size : 45.36 mm*5.36mm*3.32 mm

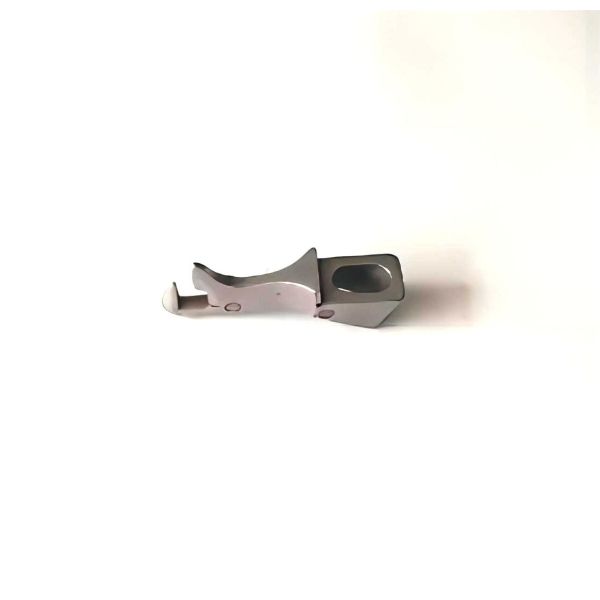

Part name: Metal injection molding parts phone accessories made from Stainless steel with high quality MIM

Different shaped non-standarded parts , can be customized according to customer's requirement.

Advantages: the shape can be customized with different shaped bore and competitive price compared with directly cnc machining.

It is very good for mass production.

Compared with powder metallurgy, casting, machining and stamping, MIM has its great advantages

1) Directly manufacturing small sized metal part (0.02-200g) with complicated geometric shapes like producing plastic parts.

2) The parts made by MIM have high relative density (95%-99%) , more consistent microstructure and higher mechanical property. The parts can be done by heat-treatment ,such as,cementite,quench,tempering. If some sizes in high-precision,the parts can also be done by afer-treatment of machining.

| Technology | Maching | Powder Metallurgy | Casting | MIM |

| Weight(gram) | 1~10,000 | 5~2500 | 1~1000 | 0.01~200 |

| Tolerance (%) | <0.1 | 0.1 | 0.5~1.0 | 0.3~0.5 |

| Density(%) | 100 | 92 | 99 | 96~99 |

| Intensity % | 100 | 70 | >95 | >96 |

| W.T. mm | 1~100 | 2~20 | 2~20 | 0.5~10 |

| Roughness(um) | 0.2~4 | 2~5 | 5 | 1~2 |

3) Compared to investment casting and powder metallurgy, the MIM parts tolerance can be held to +/-0.1~0.5%, glabrous surface , up to Ra1.6.

4) Steady quality,high efficiency and economic solution for mass production in high volume.

5) Higher utilization rate, energy saving

| Technology | Casting | Cold forming | Forging | Machining | MIM |

| Utilization rate % | 85~95 | 80~90 | 78~85 | <50 | 95~99 |

| Energy consumption (MJ/kg) | 40 | 40 | 50 | 80 | 30 |

Contact US

We provide a wide range of technical support and services for various metal or plastic power parts, including:

We strive to provide the highest quality services and support for our customers. If you have any questions or need assistance with any metal gears/machining gears/hobbing gears/sintered gears related issue, please don't hesitate to contact us.

Packaging and Shipping for Metal Gears/Machining Gears/Hobbing Gears/Sintered Gears:

The metal gears/machining gears/hobbing gears/sintered gears will be packed in corrugated boxes or wooden crates. The boxes and crates will be labeled with the product name, order number, customer name, and instructions for delivery.

The gear products will be shipped according to customer requirements. We will use reliable courier services to ensure timely and safe delivery. We will provide tracking numbers to customers to enable them to track their orders.

1) Drawings including tolereance requirement or photos or samples of products.

2) Detailed sizes of products.

3) Material of products

4) Surface treatment of products.

5) Ordinary purchasing quantity.

|

|

OEM ODM Metal Injection Molding Parts for Phone Accessories Images |